CNC spindle drive system includes spindle drive amplifier, spindle motor, transmission mechanism, spindle assembly, spindle signal detection device and spindle auxiliary device.

Amplifier: The spindle amplifier is used to receive the spindle speed and function control signal sent by the system, and implement the spindle motor control, which can be a frequency converter or a spindle amplifier dedicated to the system.

Main shaft motor: The main shaft motor is the power source of the main shaft drive, which can be the ordinary motor, the inverter special type electric motor and the system special spindle motor.

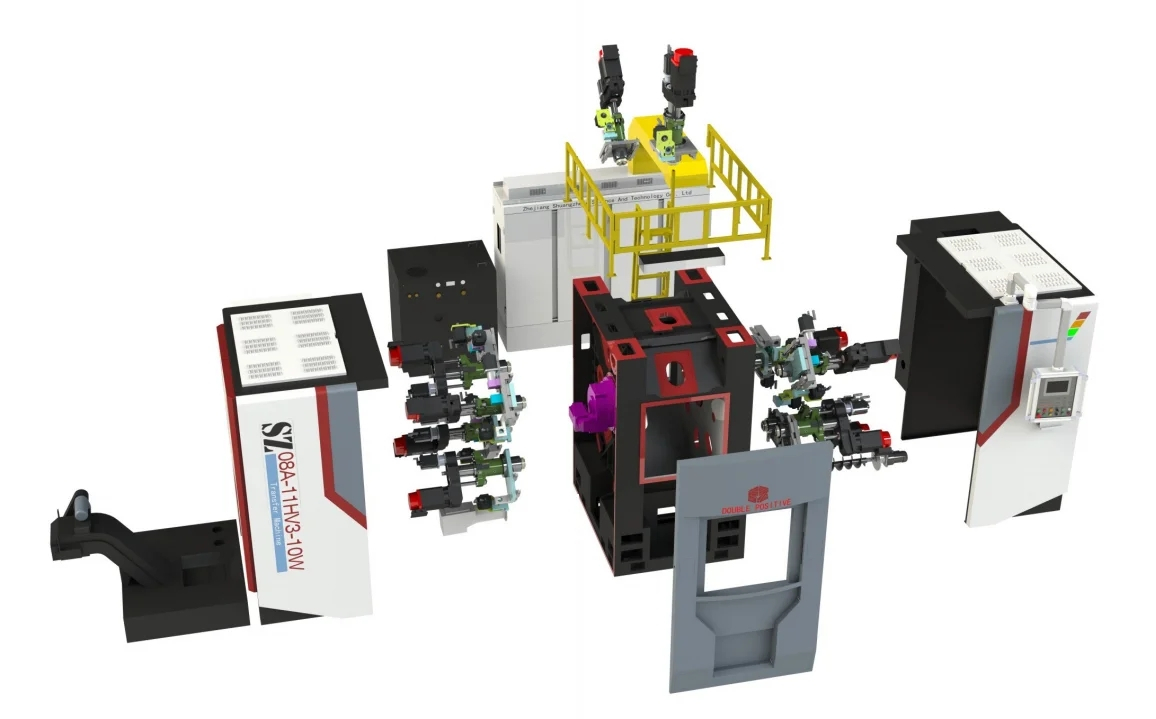

Transmission mechanism: water wheel transfer machine main shaft transmission has three main configuration modes, that is, the main movement mode with speed change gear, the main movement mode through the belt transmission and the main movement mode driven directly by the speed change motor.

Spindle assembly: Spindle assembly is a complete set of standard components. Machining center spindle assembly includes spindle sleeve, spindle, spindle bearing, butterfly spring, broach claw, etc.

Spindle drive detection device: The spindle signal detection device can realize the speed and position feedback of the spindle, as well as the signal detection of the spindle function (such as spindle orientation and rigid tapping control, etc.), which can be the spindle external encoder, the spindle motor built-in sensor and the external one turn signal with the motor built-in sensor detection device.

Auxiliary devices: Auxiliary devices mainly include spindle tool lock/release control device, spindle automatic shift control device, spindle cooling and lubrication device, etc.

water wheel transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html